A Week in sources of inspiration

19 Mar 2023

Tags: chuncaster, inspiration, jazz, paul reed smith, pickups, podcasts, prs, straps, wuthering bytes

The nature of building guitars means I tend to view them from an engineering perspective a lot of the time, somewhat removed from the emotive end result: making music. This week’s notes are going to be more about inspirations and motivations than building, so if you’re here for pretty workshop pictures then you might want to skip this week - normal service shall resume next week.

Julian Lage

Back when I was researching guitar designs a few weeks ago, notably the original Fender ‘Blackguard’ Telecaster, I discovered Julian Lage, who is a jazz guitarist that plays one of these vintage instruments still, even when live. Whilst I’ve generally liked jazz guitar for a while, something about Lage’s playing in these live performances has captivated and inspired me:

I can’t quite put my finger quite on it, but the way he plays, not overly fast or complex, but very melodically, makes it very accessible to me as jazz goes. He leaves space for the rest of the ensemble too, which is important to me. Finally, the guitar he has chosen, this vintage Telecaster, is part of the performance: the sound he gets is influenced by that choice of instrument over a more traditional arch top - the sounds are his to choose, but they’re enabled by his choice of instrument.

Since finding this I’ve been listening to a lot of Lage, and podcast interviews with him (of which more below), and he’s been both an inspiration on my personal playing but also a significant inspiration on my desire to make instruments, which was an unexpected but pleasant surprise. Watching what he can do in that live performance, the joy the audience is having, enabling that hard to define magic is what makes all the effort of building an instrument worth all the blood, sweat and (more often than I’d care to admit) tears in a build. A large part of the original inspiration when I started building guitars was witnessing my brother play a gig with the guitar I built for him, and seeing how the crowd loved the show, and feeling that in some small way I helped create that moment. Over the years, particularly with the pandemic, but also just in general as I’ve lost and found my way with guitar building, I think I’d lost the spark that gig had given me, and watching these videos of Julian Lage play has reminded me of what it is I want for my instruments: to be someone who enables that magic that happens when an artist performs and the joy it gives the audience.

Like I say, I wasn’t expecting to be inspired as I have been from this, but it’s motivated me to press on in a way I haven’t had for quite a while, and is a reminder that I need to get back in touch with people playing my guitars more.

Podcasts

I listen to a lot of podcasts, particularly as I have a 40 minute drive each way to the workshop and a 20 minute cycle to the maker space I use, so I easily get a couple of hours of podcast listening in a week. But despite that, I struggle to find guitar podcasts to listen to. At some point I reached gear news saturation, and so whilst I used to enjoy the frivolity of podcasts such as Guitar Nerds, I struggle to get into them these days, and so haven’t been listening to guitar podcasts for a while.

But looking up more on Julian Lage did lead me to finally listen to the Wong Notes podcast, hosted by guitarist Cory Wong. I think what makes this show different from a lot of guitar podcasts is that Wong is a busy performing musician, and so the conversations are much more a conversation between peers about playing, rather than “oh my, here’s this person I wish I could play like”, and so you get more of a musician’s conversation about being a guitarist, which again is what I’m interested in as someone trying to build instruments for players.

I don’t listen to every episode, which is my general podcast survival tip, but particularly interesting ones have been:

- Julian Lage (obviously)

- KT Tunstall (I still am in awe whenever I see that …Later performance)

- Robben Ford (someone I’d not really listened to before, but I enjoyed his perspective here)

If nothing else the Julian Lage interview taught me the trick to use an architect’s drawing tube as a way to transport guitar necks around - he’s been known to dismantle his guitar, put the neck in a tube and the body in a rucksack, and thus avoid checking in his guitar on flights! KT Tunstall does talk about looping, and it was interesting to learn more behind what she does - for example how important it is to have an EQ on the floor so when she’s using the guitar as a drum it doesn’t sound like a kitchen cupboard.

Another podcast I’ve been dipping into is The Process, which in which Doug Bielmeier interviews artists making experimental music about a particular piece they wrote, what the inspiration for it was and so forth. It’s much more focussed than just a general interview, and as someone who does play music, I’ve found the look at how people try to make music interesting. As a consumer of music you tend to assume it comes perfectly formed from the minds of genius, and this raises the curtain on that a little (as does the KT Tunstall interview I mentioned above).

Looking at this, and other podcasts that I’ve listened to, perhaps the trend is more I’m interested in learning about the musicians and how they work than by the instrument themselves. Again, I think I’m trying to reconnect with the use case for guitars, rather than focussing on the guitars as then end point.

Paul Reed Smith

Another unexpected source of recent inspiration/motivation has come from watching some interviews with Paul Reed Smith, the man behind PRS Guitars. PRS guitars are probably the next big guitar company people think of after Fender and Gibson; whilst their guitars (or at least the few I’ve had access to) are not for me, they are well regarded generally - indeed, at the aforementioned gig my brother played, this second guitar was a PRS SE Custom 24:

What I found inspiring about watching Paul Reed Smith talk is that, despite being the head of a guitar company for 40 years now, he as an individual seems just as passionate about building great guitars as he did when he started. He still cares about the details, he still has the confidence that he’s building something better than the others, and he’s still pushing to understand why guitars do what they do and how he can bottle the magic that certain instruments have. As a random example here he is on That Pedal Show last year:

The other thing I like is that, unlike a lot of the guitar industry, he’s not interested in pure nostalgia - he’s still chasing making a better pickup for instance, that lets you have the clarity and brightness of a single coil pickup whilst using a humbucker design to eliminate noise. He wants to innovate and push forward - despite the fact that this has cost companies like Gibson heavily due to consumer pushback (e.g., their failed attempt to have robo-tuners a standard option). But I guess PRS has less baggage to worry about than Gibson, or perhaps he understands the parts you can innovate with that don’t scare of the customers. Either way, it’s refreshing to see his engineering enthusiasm, as you can see here in this pickup video PRS made a while ago:

Like I say, his guitars aren’t to my taste, but that’s more down to looks than anything else: I’m not a fan of the shape of the guitar Tristan has there, the way the two horns form a bowl with the neck sticking out, and in the flesh I find the gloss finish to be a bit much. But that doesn’t mean I don’t appreciate what PRS are trying to achieve, and that I don’t find Paul Reed Smith’s drive inspiring.

Watching Paul Reed Smith talk about guitars and what is driving them to go forward feels like the kick I need to keep embracing the tech side of my mind more in my builds. I’ve already felt motivated to build more since I embraced using more custom 3D-printed parts in my builds, and hearing him talk makes me want to do more of that experimentation.

The challenge with listening to someone like Paul talk is that it’s very easy to become overwhelmed, like a deer in the car-headlights. There’s so many things I’d love to play with based on having let some of the things he’s said rattle around my head the last few weeks: I’d love to revisit some of my earlier designs that used a scarf-joint headstock like PRS guitars do, I’d love to do more with through neck guitars (imagine Älgen, but made all of wood) to see how that compares tonally with my other builds, I’d love to try 3D-printing my bridge parts in many materials to see what impact that has on the sound of the instruments I make. I could keep going, but you get the point. I have limited time to devote to guitar building, and there’s so much I’d like to explore when I open my mind up to the possibilities, but I have to try and focus and use the little time I have effectively.

So to that end, I’ve decided to act on just one source for now, particularly as this one will be something that I can easily fit in around my day job, and should give me some early feedback relatively quickly.

When I started designing Älgen, one of the things I considered and then dismissed was building my own pickups, due to the unconventional nature of the body, but I realised that for the prototype I could avoid that by using P90 pickups, because they mount centrally rather than at the sides like most pickups. This was an easy decision to accept, because I’m a big P90 fan, and my daily player has P90s on it. Anyway, I had enough to do, and so I stopped there. I also have been lucky to work with Matthew at House of Tone Pickups up in Chester. Matthew does a great job of taking the descriptions of what my clients want tone wise and building pickups based on that, and I’d heartily recommend his pickups to anyone.

But I feel that the pickups are a key part to what I build, so I’d like to finally try experimenting with my own pickups. Not so that I can replace Matthew, but more so I can understand what the pickup variables are, and also just to make it easier for me to experiment - pickups are not cheap, and I’d like to have the ability to experiment more freely with guitar builds without worrying about the investment in pickups before I’ve committed to a design.

I’m also not doing this to just try rebuild classic pickup designs - like PRS do, I’m interested in understanding the variables that go into making a pickup and how you can control what comes out. I’d like to play with 3D-printing different shaped bobbins for instance to see how one can impact the sound.

Pickup winding

So, having decided I want to go down the rabbit hole of pickup-winding, I need to work out what the minimal viable pickup-winding position is and how much it’s going to cost to play in this ballground. I started by watching videos of people winding pickups, and I particularly enjoyed a series by Schuyler Dean Pickups, such as this one:

I was again particularly inspired as not only does he have a nice series of basic pickup-winding videos, but he also looks at some more interesting pickup design considerations, such as this hum-cancelling telecaster bridge pickup:

Whilst you can buy pickup winding machines, including very nice ones like the one from CNCDesign or this more basic one from StewMac, I’m not looking to do this professionally, I just want to have a bit of fun and better understand this key component in the instruments I build, and as such I’m not ready to drop the better part of a grand on a pickup winder.

Thankfully I’m a professional nerd, and so the idea of making a basic pickup winder feels quite achievable, particularly as I’ve also spent time helping maintain the CNC-router at the local maker space, so I have an understanding of how CNC machines are constructed. I had a look on instructables, and there’s a few designs on there for winders, like this simple one here:

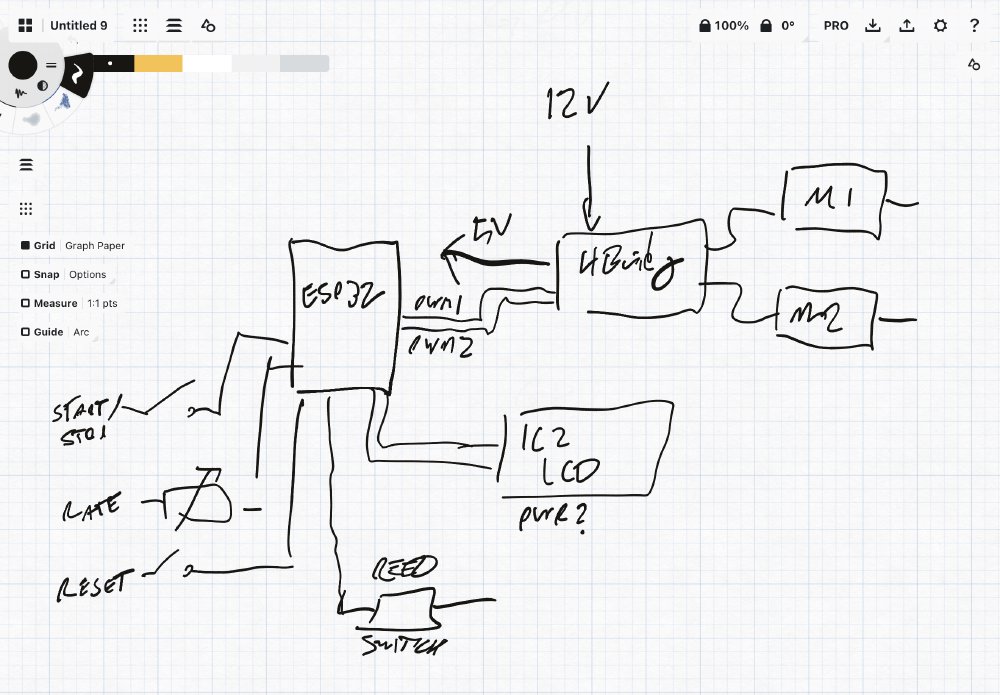

I watched a couple of these, and in the end hatched a plan to build my own little hobby pickup winder, that riffs off those designs, but also will let me evolve the machine over time to do more complex things should I want to go deeper down the rabbit hole.

My current plan is to just build the most basic thing I can to start with, but I’m going to use a slightly more advanced electronic control board (an ESP32 based board for those curious) that’ll initially be underutilised compared to say an arduino or such, but over time will let me do things like add logging so I have a history of what I wound when, let me store settings on a computer or phone for later playback, etc. But simple steps first, particularly given time is somewhat precious, and I’ll stick to the minimal start/stop and wind-speed controls and see if I can just wind a working pickup from there. I’ve ordered a bunch of parts from PiHut to let me just do a basic test of driving a stepper motor from an ESP32.

In terms of parts for the pickups themselves, just to do the basic proof of concept I’ll start with a simple off the shelf pickup kit for a single coil, and I found a source of reasonably priced pickup wire too.

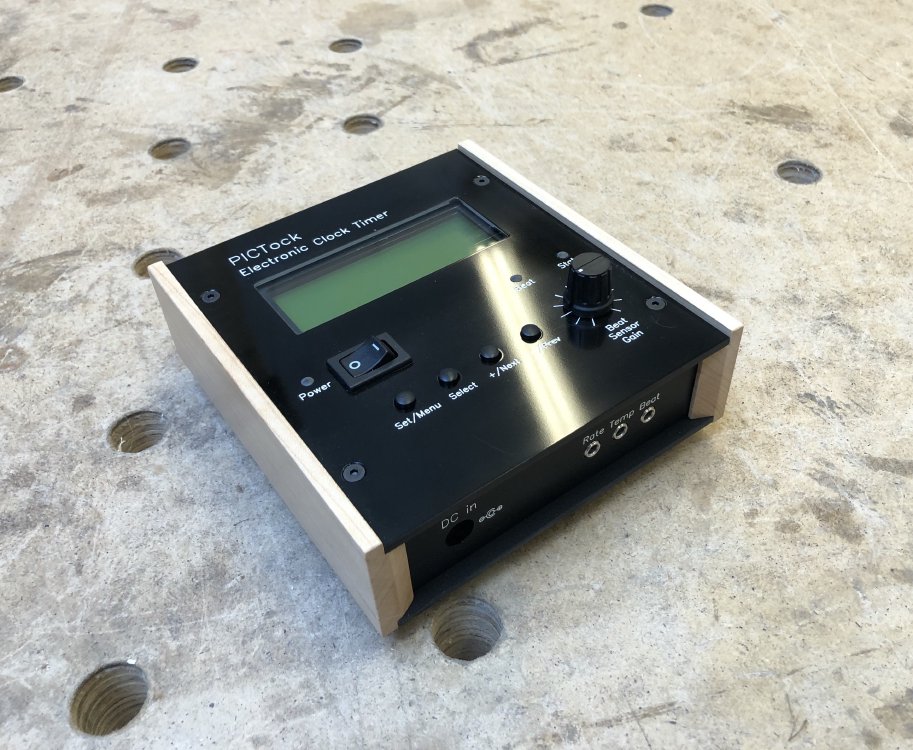

Thinking about how I’d eventually case my winder, I doubt I’d go with the 3D printed shell used in the instructables video, but rather either an all acrylic case I can laser cut, or better yet, something inspired by this case my friend Graeme made for one of his projects a few years back:

I love both the mixed mode here, and how despite being a maker project it looks like a quality production build that you’d find on a premium bit of hi-fi equipment or such. Graeme went to great lengths with this one, painting in all the labels by hand if I recall correctly.

Wuthering Bytes

I was pleased to see that Wuthering Bytes, a technology and arts conference set in Hebden Bridge, is returning this year after a long hiatus. I was an attendee for the conference for many years, and then at the last one in 2019 I actually gave a talk on how I got into guitar building having never before done any woodwork.

I look back on that talk, given before the world changed, with something of a sense of cringe: at that point I felt that building wise things were going from strength to strength, and since then I feel I’ve been knocked down a peg or two. But I also think I lost touch with the lessons I was trying to encourage others to take with that talk: I lost touch with the users of the instruments in particular, I stopped working incrementally and tried to up my game in one big leap with älgen, which I’m glad I did, but lost me that sense of continual incremental improvement.

Anyway, I’m not speaking at Wuthering Bytes in 2023, so you’ll be saved the introspective talk ;) But, as part of trying to engage with more people on guitar building, I got in touch with the organiser of Wuthering Bytes, with the idea that I’d show Älgen there, as a sort of follow up. They seemed keen for the idea, though what form it’ll take we’ll see closer to the time, but it’ll be nice to continue the story a little for those that saw my talk in 2019, to see where things can go.

Mighty Beasts

With Älgen wrapping up, I realised I needed a strap for it, but I’d used up my stock of guitar straps when I shipped out The Corvette. I was worried that I’d need to find a new strap supplier, as thus far all my guitars have shipped with a strap made by Rachel at Mighty Beasts, but she seemed to have not been active online since last 2019.

I liked getting my straps from Rachel, in the same way that I like getting pickups for my guitars from Matthew, in that I can then say that for the bits of the guitar I don’t make myself, I at least know the person who made them, and I can have a conversation with them about what it is I want. thus I wasn’t looking forward to having to find a new supplier. In particular, I liked the idea that her straps were “vegan”, which matches my desire to find more sustainable woods for my guitars.

Thankfully, before spending a lot of time looking for a replacement, I reached out to Rachel, and it turns out she’s still making straps, just on a request basis, but does plan to ramp up production again in the coming months, so that’s a relief! Älgen will get to have a nice strap, and I get to feel good that I know it was made by an individual who cares as much about their straps as I do about the guitars they go with.