A Month Out the Shop

Published 21 Jul 2024

Tags: älgen, delfinen, emf, liverpool, makefest, sweden, verkstaden

I have to confess I’m still getting used to the idea of summers being a time of travel and less time of workshoping: both because of holidays, but also because we have multiple shows I like to attend where I get to show off and present the ideas behind the guitars. This feels like a lack of progress, as its less “doing”, but sharing your work is a big part of trying to make something sustainable around it. And even when I wasn’t at guitar events I was still picking up interesting things to apply to what I do here - so this post will go over both the shows and the interesting things I found on my travels.

EMF

First we have Electromagnetic Field, aka EMF or EMFcamp. If you’ve not come across EMF before, it’s a tech/arts festival that lasts for four days out in a field in Herefordshire, with about 5000 attendees, all of whom are lovely and interesting. There are talks, workshops, installations, themed zones, and lots of the campers will form villages around a theme they like meaning there’s a bunch of mini festivals in the festival itself. It’s every other year, and with so much going on its easy to understand why people love it so much - no matter what you’re interested in, there will be something on that topic there, or you can make it happen yourself, even if that’s just talking to like-minded folk over a coffee or beer whilst sat under a tree. This was my forth EMF I think, and the second at which I’ve given a talk, having done so back in 2018, where I gave a talk on how I got started in guitar building.

This year I gave a talk on Älgen, describing how the design came about and how the different 3D-printing methods I used worked.

At some point the EMF talks will be posted online, so I’ll link to it when that happens, but for now I’ll just say from my side it went well (even if I did have the usual stage fright and manage to rush through it missing a few things), and there was a bunch of lovely discussion that took place afterwards with folk interested.

At the talk there wasn’t really a chance for people to play the guitar, and so I mentioned that the following day (the final Sunday) I’d set myself up as a temporary installation down near the bar area, which is next to a nice lake, and people could have a go. I took along my 20W Blackstar amp and a large portable battery, with the intent I’d hang around for half an hour or an hour and those who came to my talk and wanted a go could do so.

What actually happened was that for the first half an hour there wasn’t many folk around, I suspect as much fun was had the evening before, but then it was non-stop for over three hours, as the folk of EMF turned up to demonstrate what a talented bunch they were. As ever, it was lovely to see Älgen in the hands of many different types of players, and in the hands of people who might not otherwise get to play a custom-built guitar, particularly one as weird as Älgen.

The best complement was from someone who, after playing it for a while, said “I expected it to be unusual, I hadn’t expected it to be good” or words to that effect. Which I think is the general sentiment I’ve had from folk who’ve played Älgen: they come for the novelty of its construction, but then find it’s actually a good guitar to play. This makes me very happy, as that’s what I was hoping for: Älgen always needed to be a good guitar first and foremost, despite the unconventional approach to construction.

After a few hours whilst the guitar was still going strong, I was starting to flag in summer heat and we had to get back to Cambridge, so in classic showperson style we had to head off leaving the people wanting more - there were a couple of folk who wanted to have a go that didn’t get chance, and for that I’m sorry and hopefully we can have another chance before the next EMF in 2026!

Sometimes at EMF dreams can come true. And indeed, sometimes you don’t know you had those dreams until someone comes along and makes them happen for you.

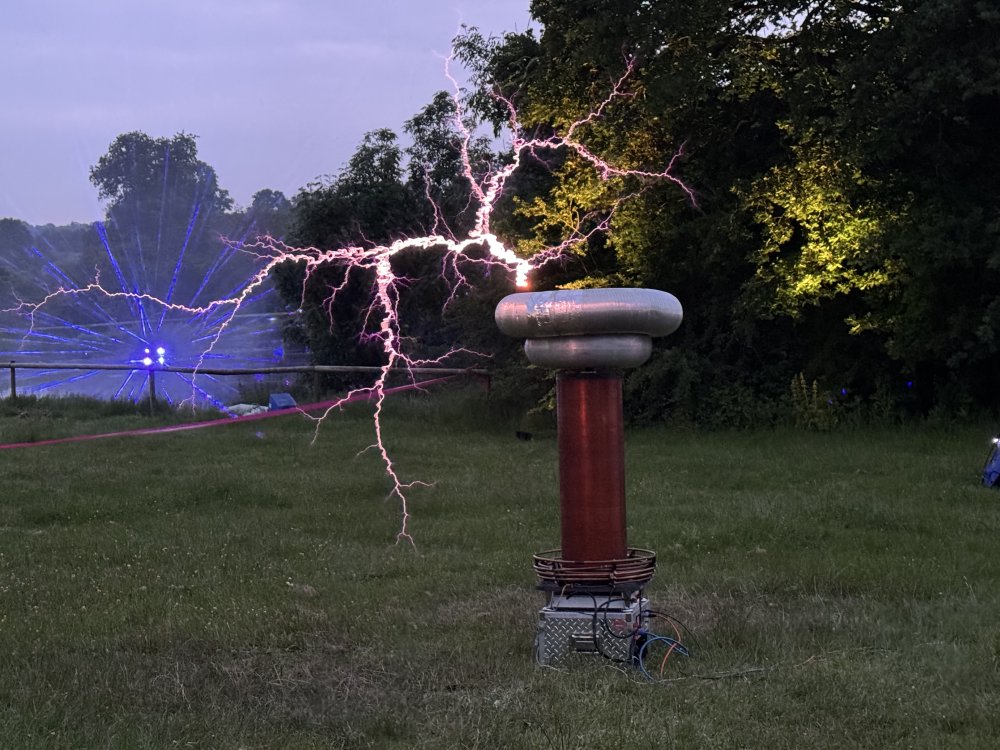

One of the installations at EMF this year was a giant tesla coil, ran by Derek Woodroffe of Extreme Electronics. You might remember these things from high-school physics class demonstrations, but if not they’re high voltage devices that create nice electrical arcs like this:

However, as cool as seeing a giant tesla coil is, this one had been hooked up to a set of musical bits and bobs with the help of Steve Conner, and on the first night there we got to see someone performing with a theremin using the tesla coil as a very loud speaker. I spotted the next day that they put out a request on mastodon, asking if anyone else had an analog instrument they’d like to plug into this, and well, you can perhaps now see where this is going… I got to play Älgen through a giant tesla coil!

It’s like the most visceral and dirty fuzz pedal ever - it was amazing. Normally I hate playing in front of people as I’m not really that good a guitarist - I play to amuse myself, but the moment I think someone might hear me I go to bits. Here though the large crowd that was there to see the tesla coil just vanished for me, there was this tunnel vision between me, the guitar and the tesla coil, and nothing else really mattered. So a great cure for stage fright :)

I’m hugely grateful to both Derek and Steve for making this a thing that could happen - I feel unbelievably lucky and privileged to have been afforded this opportunity, and it’s genuinely going to be a thing I remember for the rest of my life.

Despite the impression I painted thus far, I wasn’t the only one with a guitar at EMF, far from it. There were a couple of musical things going on at EMF this year, and one I was particularly keen to see was Feral Five, who I know of via my old friend Jonathan Hogg, as he’s been doing live visuals for their shows. FF do a mix of live instruments with electronica, a hint of 80s, but also songs very much themed on the modern technological mess the world is. Jonathan was one of the organisers at EMF this year, and so I guess it was perhaps destined to be Feral Five would play a set, and Jonathan (left in the photo here) did indeed do the live visuals.

Due to the fact that there’s half a dozen things going on at once at EMF the turn out was not the largest, but it was still a great set, and afterwards I went and got some music and merch from Feral Five’s bandcamp - definitely worth checking out, though I am sad I couldn’t order some gold techno-mage robes as the band were wearing that the show, as I feel they’d go down well in my day job as the technologist in a team of ecologists.

Liverpool Makefest

A month after EMF it was then Liverpool Makefest time. I’ve been lucky to be a regular fixture at Makefest, having done it every year its run since 2017, and I have to admit feeling slightly sheepish this year, as I didn’t really have a new angle for this year. The last year in the workshop has been about the grind of learning to paint, and I felt I’d not done anything new since last year on the 3D-printing front, so wasn’t sure what I was adding that I’d not said before. But I’m glad that I still went along, as it turns out I was mostly wrong about whether it’d be of interest to the people of Liverpool.

This was my stand this year, and this was a great moment of realisation for me. This is the first time I’ve set up all these guitars together, and said “this is what I do” - there’s no guitars here that are other people’s designs, it’s all me and reflecting what I’m interested in building. In all the struggles of the last year, this was the first time I’ve stepped back at had on show all these builds, and realised that there’s a cohesive link between all these different instruments, and I’m not just a one trick-pony with Älgen being the star and everything else an also-ran. There’s a design DNA that links all three instruments here, which might not be immediately obvious, but is there if you look for it: shared lines, all use 3D-printed and laser-cut parts, either overtly or subtly, and they all share a similar playability and feel as an instrument. Regardless of what the audience got from Makefest, I found this realisation a rewarding one, and so I’m glad I didn’t chicken out of the opportunity.

As ever, the stand was busy all day with people coming along to see the instruments and to get to play them. I’ve come to love the fact that, in the same way Derek and Steve enabled me at EMF, I get to enable people to come to a library and play guitar through a 20W valve amp and rock out - this in itself is a privilege too. A couple of times I handed the guitars to folk and they were “are you sure, this is a library, can we do this”, and being able to be the one to say yes to that means something is going right in all this :)

One thing I needed to do for Makefest was get new cards made, as I was low on them, and so this was also time to pull the trigger on the re-brand, from Electric Flapjack to just using my name. That has been something I was switching for a while - all the recent guitars have my name on the headstock (or on the back in the case of Älgen that doesn’t have a headstock), and the website actually put up that logo for those pages pertaining to those instruments at the top. But I finally bought a domain and migrated the website and contact info over (the old ones will work also for as long as I still see traffic coming that way). Why did I do this? Mostly because people are buying a guitar from me as an individual - they commission me because they see what I’ve been doing and want something like that. They want a guitar where the provenance is clear, and so I think this just makes that a little more obvious. Besides, the term electric is a little limiting should in the future I want to make an acoustic instrument.

With that done, I got a bunch of glossy promotional postcards printed for Makefest, and had an unexpected failure with them. Normally I make business cards, and last year even plectrums, for people to take away - and usually they do get picked up over the day, so I figure it’s worth doing. This year I thought I’d try make something a bit more memorable, so I made a set of nice postcards from the better photographs I’ve taken this last year: you can see them scattered on the table next to Älgen in the first photo there. I tried to put some of my limited design chops into them too, with a nice border and logo and all that, and I got them printed on nice shiny card at Moo.

Sounds all good in theory, but in practice people would take the last few of my old business cards, but not the shiny new postcards. When I tried to suggest people took the postcards it turned out they looked too nice, so they assumed they weren’t to be taken by people 🤦🏼 So it seems I need to make things that are not so nice looking next time to they have more of the affordance of being takeable.

The other amusing thing was I did five variations in the end, two of which had Älgen on, and then the rest of the other guitars, and all the Älgen postcards went, and only a few of the other ones. Seems obvious in hindsight, but I guess next time I’ll skew the deck more appropriately.

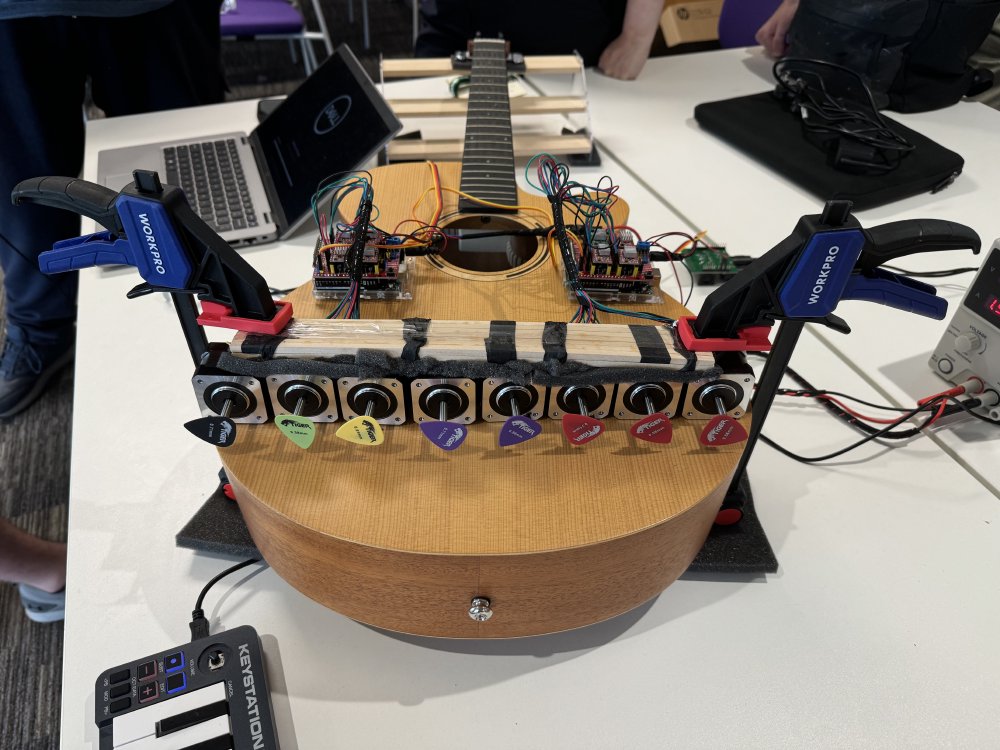

Whilst the rain and some football match meant that it was a bit quieter this year at Makefest, it was still the case that it was non-stop all day, just I got to spend a bit more time with each person stopping by, which was nice. But this meant once again I did a poor job of seeing what else was going on. The one exception to this was I went to see a group of students from John Moores University, mentored I believe by Jan Lunn, who had made this wonderful device:

What is happening here is that there is a series of stepper motors that are programmed to make notes: with these motors as you drive them you’re effectively pulsing them at a frequency rather than continuously driving them, and that pulsing can be made to match a note. However, that pulsing will be very quiet unless you have a way to amplify it, and so they’re using the body of an acoustic guitar for that! The plectrums you see are purely for show, as they spin around when the motor is playing a note, but it’s the motor’s vibration that is key here.

Whilst I think they had just chosen the guitar as a mix of function (it’s a ready made sound box) and looks (it’s a musical instrument and they’re making music so it fits), there is a benefit I think to choosing a guitar for this, in that acoustic guitar bodies are designed to resonate at certain frequencies well, those that match the kind of music you’d expect to hear on them. So whilst you could use an box to amplify sounds, this particular box is designed to do these kinds of frequencies well.

I was lucky to catch it, as they’d started to pack up when I finally made it away from my stand, but they quickly did a demo for me and a couple of other makers that were doing a similar last minute run around to see things, and I’m really glad I did, as it sounded great. I wonder what would happen if they could put the motors on the inside and then string it up to play along with?

One other, literal, take away from Makefest was a wonderful sheet of recycled plastic kindly gifted to me by Pat from Neston High School’s maker space. Pat’s been doing great stuff there for many years, and in particular they’ve been working a lot this last few years on recycling plastic, where the kids will collect plastic, sherd it, melt it, and turn it either into sheets or injection mould it straight into products like plant pots.

Anyway, whilst I was away seeing the motor-resonating-guitar above, one of Pat’s students dropped off a sheet of plastic for me to use, as I’d been commeting to Pat earlier in the day how beautiful I thought the re-cycled plastic looked:

When I first saw the sheet I’d assumed someone had dropped off an abstract oil-painting until I realised what it is! The colours and the patterns are wonderful, and so I need to find a way to make use of this in an instrument that somehow preserves that look. A pick-guard is an obvious option, but I feel there must be something more I can do with this. Either way, it’ll be a return to CNC-routing for me, as this plastic isn’t laser safe.

But what a gift! An honour to have received it from the Neston High School team, and I just need to make them proud of what it becomes!

Svenska Sommar Semester i Stockholm

We took a week’s holiday in Stockholm, of which isn’t of much interest here, other than I did happen across another luthier that was building some unusual and interesting guitars. We were just walking through Södermalm, generally seen as the hipper side of Stockholm, when I spotted in a doorway a poster for an unusual guitar:

Called The Tool, it is an attempt to design a guitar from a different angle from how electrics have been classically done. I spoke to the builder, I believe called Mats, who said he worked with an industrial designer on the project, but both of them had the strict understanding that it was an instrument first, not a project where a designer is just added to make it pretty rather than functional. For instance, the guitar design is optimised to be played sat down as much as stood up - a recognition that when working on tracks guitarists spend a lot of time these days sat in front of a computer. He told me the first eight were built by hand, and then slowly they moved it to being built by a guitar production house, and each one of those first eight was different from the first, as they learned more about what worked and what didn’t. Time was also a factor - on those first versions parts they thought good initial after two years wore down - but there’s no way to know that without having the instrument exist and be in use.

I’ll touch on this again later, but it was wonderful to understand that this is all part of the process, that things out the gate you can’t know that they’ll be perfect until you’ve applied time, so you do the best you can and put it out there and react when things happen. It’s somewhat funny that I don’t feel this, given I’ve spent a career in software where in the field updates after shipping are the norm, but I feel for my guitars admitting this is a sign of weakness, rather than as Mats told it being the way it has to be.

Anyway, it was great to meet another luthier and get more understanding of the longer term look of what it takes to build an instrument. You can see a demo of their guitar in action here on youtube and get a feel for its ergonomics in action - there’s no unnecessary material here, but what is there serves an important purpose:

Goodwood Festival of Speed

Bare with me on this one, it is related! I went to Goodwood Festival of Speed, to go see a lot of silly and expensive cars on stands and driving up a hill. I like the mix of engineering and design that goes into fancy cars, particularly as I’ve had the good fortune to actually drive some smaller track cars in the past and enjoy the technical challenge that is. My friend that I went with and I spent a good amount of time looking at the latest and greatest super- and hyper-cars, taking in their details and enjoying their looks and sounds.

So what has all this got to do with guitar building or making? Firstly, when you get up to the more fancy car level, you are going somewhat boutique - your high end supercar brands are building things to a template, but customised for each customer, similar to what I do with guitar commissions: you’re getting a known thing, but made to your needs, and so it was interesting to walk around the paddocks and work out where the line was drawn for different models.

But there was another aspect to my viewing. Like a lot of makers, I beat myself up a lot of where my execution falls short of my expectation, and I lose sight of the fact that this tiny detail that is hyper-visible to me as the maker is in fact invisible to most people. I know from all the experiences I’ve outlined above that when people play Älgen they don’t see the things that in my mind I fell short, they see where I’ve created and added things first. It’s hard to shake that view though.

At Goodwood I did go there with a deliberate attempt to look at these cars from a maker’s perspective - what materials have they used, how are they joining this to that, etc. And in doing so I started to see the things that I’d not otherwise have spotted: there’s details in these seven figure cars where as a maker I’d think “on no, I can’t ship that”, but these things are shipped and in fact being celebrated and adored by thousands of people around me.

For instance, I’m a big fan of boutique car builder Pagani, and they had a bunch of their Zonda cars on display. My favourite was this car in blue carbon-fibre with yellow pin-stripes, but as I went around the car I spotted that the door seals were not the tidiest:

A tiny detail, lost in the rest of the car, but for me stood out as I went looking for the up close.

Then there was the Rimac Navera electric hypercar, where it was less a build detail, but more a design detail that would have bugged the heck out of me if it was my design: the charging socket is in a place where you end up resting the cable on a ridge in the bodywork, so they had to put a towel down to protect it.

It’d bug me as a designer, but they shipped, and people love the car.

The point here isn’t to neg on these vehicles that I enjoyed seeing and find inspirational as the intersection of design and engineering, rather to try realise myself that very few things stand up to really close scrutiny, even seven-figure hyper-cars. These things are adored by people for existing, which is far more important than hiding away something that has a few things that bug you.

Refections

At both Makefest and EMF it was great to both get the guitars I’ve built into the hands of people and to get a sense of where I am as a builder, seeing the collection of guitars come together as one thing was a reminder of how far I’ve come. At Makefest I got a series of queries about buying guitars that I wasn’t really prepared for but should have been (particularly given I made marketing material), so I need to have some answers down pat for that. The first half of that is that I’ve finally put an orders page that lists the current guitars I have in stock with a price on them. The next stage will be to get a page up to help guide people on commissions, the models I can build, what the variables are, and some range then of cost (commissions are always priced based on the specifics people order). And similarly I need to work on spreading the word beyond my website - the shows are a great start to that, but don’t scale well.

Now I’ve cleared the backlog of guitars, it’s important that I get a handle on this, as not just to cover the workshop costs, but I have ideas and aspirations for where I can take Älgen as a concept, but to do that I need to be able to fund it. For example, I’d love to do a larger metal print for the body - but at that point I really need to know there’s a home for the guitar before I commit to the costs for it. I guess that then is a good motivation for putting the energy into this side of things - I’m not really driven by profit, but the idea of being able to do more and bigger things, that’s a good motivator for me.