A week briefly in the shop before, well, you know

24 Mar 2020

Tags: prototypes, the corvette

I’ve kinda lost track of time, as I suspect a lot of people have, of late, so apologies these are a little tardy; it’s not all social distancing related, I did have a sudden rush job for one of my software clients come up and that kept me busy too briefly.

Last week started off very well: having set up my bench at the end of the previous week, I then spent Monday moving in my stuff (of which there was quite a lot!). Once I’d done most of that (admitted not all, as it was a bit dull) I did then go back to look at the in progress guitars that I’d put on pause until I found a new home that I was looking forward to resuming.

The neck for the Corvette is ready for fretting, but as was inevitable I realised I’d forgotten my arbor press bits at the old workshop, so I could start that yet. I did go over and get it ready for that: I rolled over the edges of the fretboard, gave the top level a final sand down with the radius block (once the frets are in, it’s much harder to clean up any slight marks or such), and double checked the fret slot depths. So this neck is now ready to go.

I also need to make a bridge drilling/routing jig for this. This will need to be laser cut at Makespace at some point, but at this stage last week I was already practicing social distancing, and the idea of going into Makespace for something clearly not essential to survival didn’t appeal.

The other guitar I have on the go is a final Mustang style offset build:

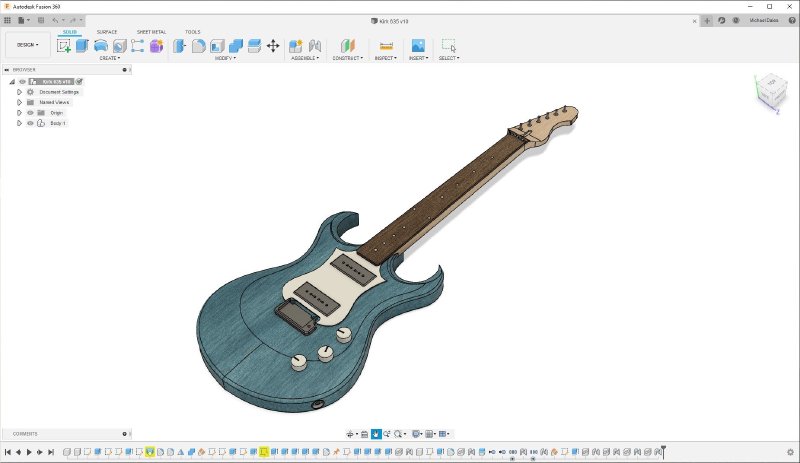

This needs the neck cut. For this I’d ordered some lovely A grade birds-eye maple, and the bit I got is big enough for two necks, which is great. I don’t currently have a third guitar in the commission queue, so I’m going to use this to make a prototype build of my Kirk model, which I was showing as a CAD model here a month or so ago:

If anyone is interested in this when it’s finished, let me know: as a prototype build I’ll do you a deal, and if you get in at this early stage you can specify pickups/colour etc. for it.

The main thing that I realised when planning the neck was that the new workshop, whilst it has a lot of lovely things in it, does not have a bandsaw! Whilst it’s always been the intent that I’d still do bits of the guitars at Makespace (e.g., the laser etching I do for marking up the fretboards), I was hoping to do the majority at the new workshop, and for my current build process the lack of a bandsaw is a major gap that I either need to fill or change my process to compensate for.

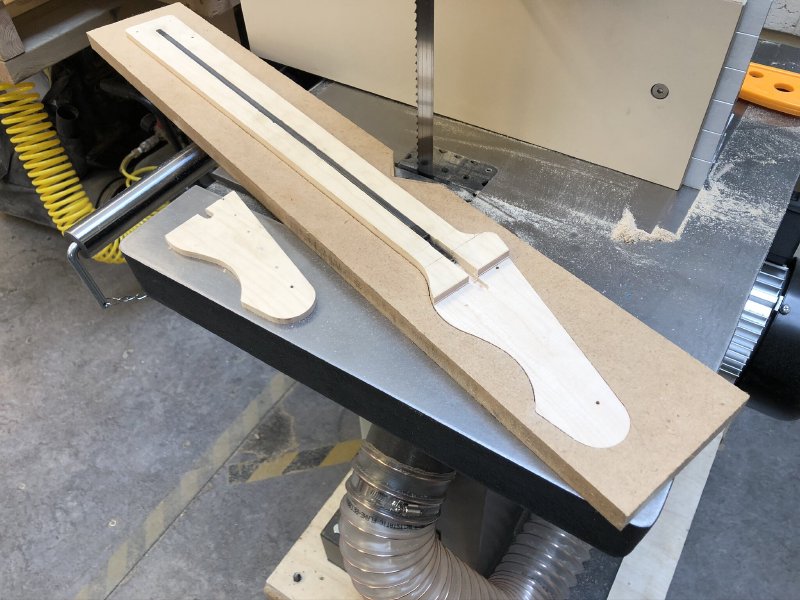

I have two main uses for a bandsaw, one of which any old bandsaw would probably do, and one of which requires a very well set up bandsaw. The first use is just removing most the excess wood when I’m using a template:

For this I need a moderately powerful bandsaw - a hardwood guitar body that’s close to two inches thick would certainly push a cheap small bandsaw to their limits - but it doesn’t need to be very precise. However, for the second use I have of the bandsaw I need it to be spot on in terms of blade alignment and tension (to stop it wandering about):

Here I remove the face of the headstock, and for that I want it to be a perfectly parallel cut to the face the fretboard will be mounted on, and I want it to be a consistent thickness. It also means I need a bandsaw with a clearance of at least 120mm, whereas most more affordable ones are 90 to 100 mm. At Makespace I was only able to achieve this thanks to the work Graeme did in getting a very nice large bandsaw that he set up well. However, at roughly £1500 this is more than I can afford right now, and it requires a lot of space.

So, I have two options here: either I find a midrange bandsaw that will meet my requirements still (the one at Makespace exceeds my requirements by quite a bit in terms of throat size etc.). Or I get a more budget bandsaw that’ll cope with the roughing side of things for removing most the excess when using a template, and then I find another way to clear the headstock - perhaps using a hand router in a jig.

Thankfully I now have time to do such research over the coming weeks whilst the UK is staying at home to deal with the current virus situation. I suspect many nerdy youtube videos on this topic are in my future.

The other thing I’d like to use some of this non-workshop time for is getting back in to CAD, as I’ve not done that for a while. I really enjoy the CAD process, but for most the last year I’ve just been working from models I made the previous year so haven’t had to do much new, and I miss that side of things.

So, to help me find things to do in CAD, I have an offer: if a couple of readers out there would like me to design you a guitar, with no expectation to actually buy it, just to go through the process, get in touch, as I’d enjoy that. I definitely find designing for people (who always have some unexpected request or idea) a lot more fun and rewarding that just doing abstract designs, so in this way hopefully it’ll be fun for someone to have their guitar designed and I’ll get a lot out of it too.

I feel at this stage it should be obvious, but the Newmarket show I was hoping to make my first guitar show as an exhibitor has been postponed indefinitely - I’ll let you all know when that comes back as a definite thing.

Finally, please do all keep well and safe - stay at home, take care of each other, and all that jazz. It’s a weird old time at the moment, and I just want to wish you all well through it.