A week out the shop

Published 30 Oct 2018

As has been the theme of the last few weeks, I’ve been flat out with contracting work again, and failed to get into the shop at all during the week, and at the weekend I went to the Mozilla Festival, a sort of technology festival ran by the Mozilla Foundation (the people who make the Firefox web browser). I imagine it’ll be another busy week coming, and then I hope to get back into the shop again.

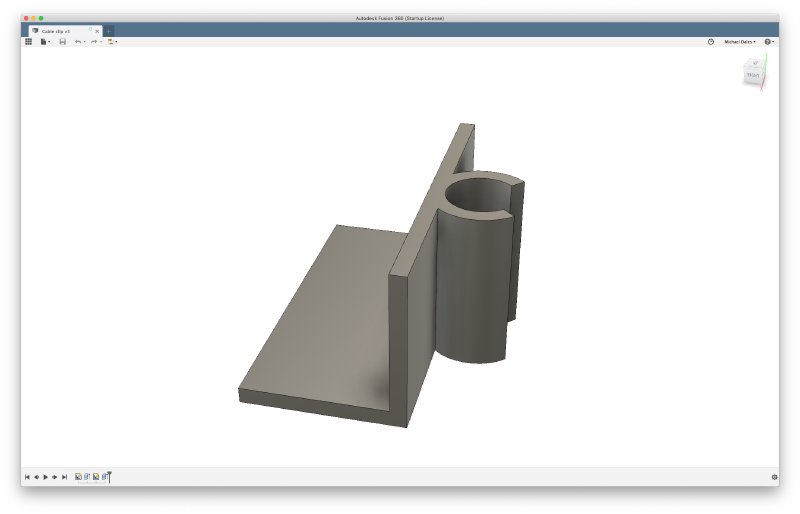

The one thing I did manage to make was a small set of clips to try keep the microphone I bought for my amp straight. I have a low profile Sennheiser e609 microphone, and like a lot of people I simply drape it over my amp, looping the cable around the amp’s handle to keep it from slipping. This works fine in theory, but in practice you’ll find your mic cable has a natural twist in it, and getting the microphone to sit perfectly parallel to the amp face is a very frustrating experience. To try and help keep things aligned I made a simple pair of clips that hold onto the cable and provide a flat surface to rest on the top of the amp, helping me align it better.

I made a front and a rear clip with slightly different designs: the rear one has an extra section to hook on the rear lip of the amp to stop the weight of the microphone dragging the cable forward, and the front one just has the plate to stop the cable twisting. It took me a couple of goes to get the sizing right, but here’s the clips in situ:

And as you can see, it’s kinda working. They’re not a great solution - you can see teh front clip is at an angle due to the way the cable bends over the front lip, and I’ve not got the balance quite right between the tightness of the clip on the cable and the ability to squeeze the cable into the clip. But it’s good enough for now, and better than the previous solution of just wrapping it around the handle and hoping it’ll sit in the right place.

To me the best thing was that it took me 30 minutes to go from idea to having a parameterised design in CAD that I can readily tweak to having the first printed prototype: all this practice is paying off.

The only other thing I’ve done guitar wise is order some grain filler for the Recovery Offset’s body. Whilst normally I like to stain my guitars, the recovery offset is made from a body and a neck that the CNC router tried to ruin, and thus they have obvious patches on them. A friend has a spray booth setup for painting, so I’m going to use this as an excuse to learn how to paint a guitar properly. To ensure a proper finish though I’ll need to apply grain filler to the ash body (if I want a flat finish, which I do), and thus I’ve got some of that on order, which hopefully will turn up before the end of the week.